INDUSTRY NEWS

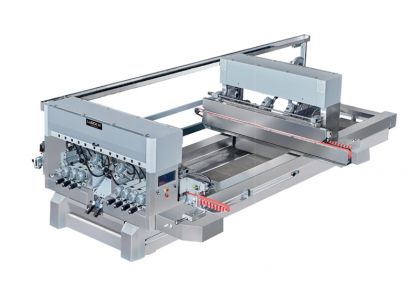

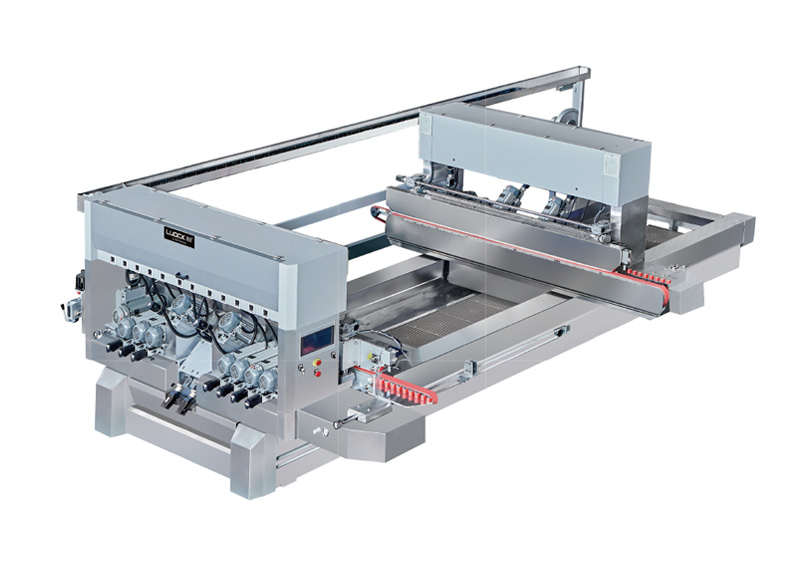

What are the advantages of glass double adging machines?

As a key equipment in the modern glass processing industry, double edging machine is designed and functioned to improve production efficiency, ensure processing accuracy, simplify the operation process and other aspects. The wide application of this equipment not only changes the traditional glass processing mode, but also provides strong support for the rapid development and technological progress of the industry. Specific analysis is as follows:

1. High-efficiency production performance

• Simultaneous processing of two edges: the double-edged machine is able to grind both edges of the glass at the same time, which greatly improves the production efficiency compared with the single-edged machine.

• Reduced inter-process transfer: The advantages of the double-edged machine are particularly obvious when processing large-size and thick glass, as it reduces the repeated handling of glass during processing and shortens the processing cycle.

• Continuous production lines: the high productivity of the double-edged machine makes it an indispensable part of a continuous production line, especially in scenarios that require high volume production.

2. High-precision machining quality

• Precise grinding: The use of high-precision grinding tools ensures the precision of glass grinding and meets the requirements of high quality standards.

• CNC technology application: Fine control is achieved through CNC equipment, ensuring high precision and consistency in the processing.

3. Easy operation process

• User-friendly design: Bilateral machines are designed with ease of operation in mind, enabling operators to get started quickly and simplifying the operating process.

• Automatic control system: The advanced automatic control system reduces the possibility of human error, simplifies operational complexity and improves operational stability.

4. Wide range of applications

• Adaptability to different specifications: According to the different widths of the ground glass, the bilateral edge grinding machine has small, medium and large sizes, which can adapt to the needs of glass processing of different specifications.

• Diversified processing capability: capable of completing a series of processing such as rough grinding, fine grinding, chamfering and polishing, applicable to a variety of glass processing needs.

5. Embodiment of technological innovation

• Introduction of advanced technology: the application of bilateral machine reflects the pursuit and application of high and new technology in the industry, and promotes the innovative development of glass processing technology.

• Continuous technical optimisation: With the continuous progress of technology, the bilateral edge grinding machine is also continuously optimised and updated to meet the market demand for higher precision and efficiency.

6. Improvement of economic efficiency

• Reduced production costs: Efficient production methods and reduced manpower requirements help to reduce production costs and improve the economic efficiency of the enterprise.

• Increase added value of products: The precise and smooth grinding effect enhances the added value of glass products, which wins more competitive advantages for enterprises in the market.

7. Adaptable design

• Flexible Mechanical Adjustment: The design of the bilateral edge grinding machine takes into account the processing needs of glass of different thicknesses and sizes, and has better adaptability and adjustment flexibility.

• Meet special needs: able to cope with special shapes and sizes of glass processing, increasing the application range and applicability of the equipment.

8. Guarantee of production safety

• Stable operating environment: Stable equipment reduces the risk of accidents that may occur during operation, providing a guarantee for production safety.

• Reduced labour intensity: the increased degree of automation reduces the physical burden of the operator, creating a safer and more comfortable working environment.

In addition, on the basis of an in-depth understanding of the advantages of the glass bilateral machine, it is worth noting that when selecting and using the bilateral machine, the following factors should be considered to ensure optimal performance performance:

• Select the right model of equipment according to the enterprise's own production scale and needs, so as not to be too big or too small to affect production efficiency and quality.

• Perform regular maintenance and inspection of the equipment to ensure that the machine operates in optimal condition and avoid production delays and losses due to equipment failure.

• Strengthen the skills training of operators to ensure that they can master the operating procedures of the bilateral machine and give full play to the performance of the equipment.

Overall, the glass bilateral machine has become one of the important equipments for modern glass processing enterprises by virtue of its multiple advantages such as high efficiency, precision and convenient operation. It not only greatly improves production efficiency and product quality, but also promotes the sustainable development of the entire glass processing industry through technological innovation. For enterprises engaged in glass manufacturing and processing, the rational use of the advantages of the bilateral machine is one of the key strategies to enhance competitiveness and expand the market.