INDUSTRY NEWS

Why you need to pay attention to strength when operating a double edging machine?

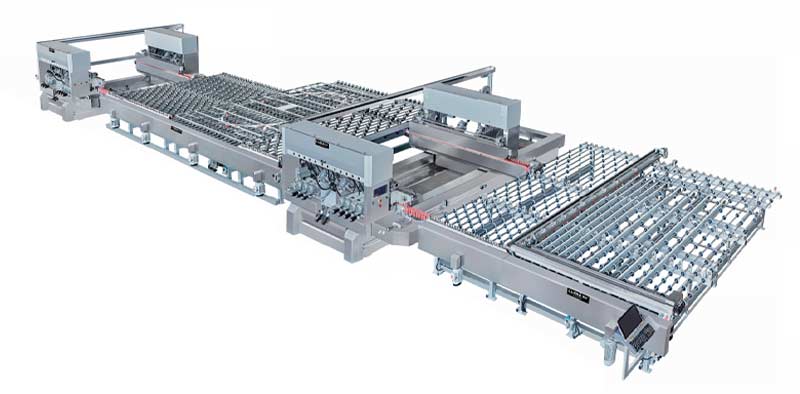

In the glass processing process, the use of double edged machines to grind and polish glass is an important step in ensuring the quality of the glass product. The following is an in-depth discussion of why you need to pay attention to the strength of your glass double edgers when operating them for calibration, as well as relevant operational recommendations:

1. Ensure processing quality

• Avoid grinding reticulation: Excessive grinding effort will form visible grinding reticulation on the glass surface, affecting the appearance quality of the product. According to the industry standard, the width of grinding mesh stripe should be controlled below 0.1mm.

• Prevent edge damage: improper control of strength can easily cause chipping, rounded edges and other phenomena, high-quality bilateral machine chamfering should be uniform in size, sharp edges and corners, no knife lines and hazy edges.

2. Ensure operational safety

• Reduce the risk of accidents: moderate operating strength can reduce the risk of accidents in the operation of the equipment, to protect the safety of the operator.

• Prevent equipment wear and tear: appropriate strength helps to extend the service life of the equipment and avoid equipment damage caused by excessive force.

3. Improve machining accuracy

• Accurate grinding head adjustment: Correctly adjusting the height, angle, perpendicularity and position of the grinding head to ensure that the contact distance and angle between the glass product and the grinding wheel are uniform and appropriate is crucial to improving machining accuracy.

• Balanced grinding pressure: Keeping the grinding pressure of the grinding head on the glass balanced can effectively avoid uneven cutting and ensure the consistency of glass size and edge processing.

4. Optimise material utilisation

• Reduce material waste: By controlling the grinding force, it can maximise the use of glass raw materials and reduce material waste caused by improper operation.

• Improve product yield: Moderate operating force and precise machine calibration combine to improve the yield of glass products.

5. Enhance equipment stability

• Maintain smooth operation: Stable and moderate operating force can make the double edged machine run more smoothly during processing, reduce mechanical vibration and improve processing efficiency.

• Extend machine life: Uniform force reduces the wear and tear of mechanical parts, thus extending the service life of the whole machine.

6. Enhance work efficiency

• Accelerate machining speed: Under the premise of ensuring machining quality, reasonable grinding pressure can moderately increase the grinding speed and shorten the machining time.

• Reduce the frequency of calibration: Accurate force control reduces frequent calibration and grinding head adjustments caused by operating errors and improves the overall working efficiency.

7. Saving energy consumption

• Reduced energy consumption: Correct force control not only improves machining efficiency, but also reduces the energy consumption of the equipment, in line with the requirements of energy saving and emission reduction.

• Reduced subsequent costs: Reduces the rate of defective products due to poor processing, thereby reducing subsequent rework and repair costs.

Combined with the above analysis, when operating the glass bilateral machine for calibration, pay attention to the strength is not only to protect the processing quality of the product, but also to ensure the safety of the operation process, but also to improve the processing accuracy, optimise the use of materials, enhance the stability of the equipment, improve the efficiency of the work as well as save energy consumption. Operators should strictly follow the operating procedures of the equipment and carefully adjust the parameters of the grinding head to ensure that the strength is appropriate and evenly distributed. This will not only produce high-quality glass products, but also bring higher economic benefits and market competitiveness for the enterprise.

In addition, manufacturers should also consider the following points when using bilateral machines to process glass:

• Regularly maintain and inspect the equipment to ensure the normal operation of each component.

• Strengthen the skills training of operators to improve their proficiency in the use of equipment and their ability to handle problems.

• Adopt suitable grinding wheels and other consumables to suit the needs of different types and sizes of glass processing.

• Pay attention to the technological development of the glass processing industry and update the equipment and technology in time in order to improve production efficiency and product quality.

In summary, you can use the glass bilateral machine more effectively, and also ensure the quality and productivity of the product. On this basis, the importance of attention to the strength of the operation of the glass bilateral machine can not be ignored, it is directly related to the quality of the product, production costs and the brand reputation of the enterprise. Therefore, in the actual operation, the operator must strictly follow the standards and make careful adjustments to ensure that each process meets the expected standards, laying a solid foundation for manufacturing high-quality glass products.