INDUSTRY NEWS

Glass double adging machine maintenance manual: fault identification and handling tips

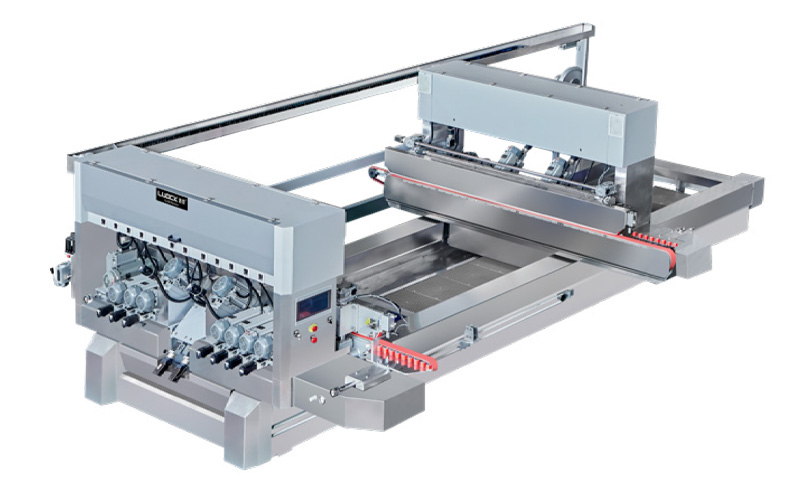

Glass Bilateral Edge Grinding Machine is a kind of equipment used for flat glass double straight line edge grinding, which is widely used in the process of deep processing of glass in construction, furniture, decoration and other industries. The following will introduce the fault identification and handling techniques of this equipment to ensure stable operation and productivity:

1.Daily maintenance of the equipment

● Cleaning and Maintenance: Regularly clean the broken glass and dust on the surface of the equipment to avoid scratching and damaging the equipment parts.

● Lubrication: Regularly lubricate the movable parts of the equipment to reduce wear and prolong service life.

● Check fasteners: Check and tighten all screws and bolts regularly to prevent loosening due to vibration.

2. Pressure frame adjustment

● Checking the height: The height of the hold down frame needs to be checked before each shift to ensure that it can correctly hold down glass of different thicknesses.

● Confirm the grinding point position: Make sure the water hose is aligned with the grinding point position before processing to prevent the grinding head from overheating due to insufficient cooling.

3. Grinding head inspection

● Grinding ratio: Confirm the cutting ratio of the grinding head by using glass of the same thickness as the processed glass to avoid chipping at the upper and lower edges.

● Grinding head position: Do not arbitrarily adjust the position of the grinding head or the travelling gap, except for the inward and outward adjustments, so as not to affect the grinding quality.

4. Maintenance of cooling system

● Water pressure check: Ensure that the water pressure of the cooling water is high enough to provide sufficient cooling effect.

● Pipe unclogging: Regularly check whether the cooling pipes are unclogged, especially when using the linear edge grinder, to prevent clogging by brush bristles and other debris.

5. Electrical system maintenance

● Power management: switch off the transmission, grinding head, water pump motor, etc. in the correct order when switching off the machine, and switch off the main power supply.

● CVT adjustment: Adjust the speed of the CVT in the open state to prevent damage to the governor.

6. Transmission system inspection

● Ball Screw Maintenance: Keep the double linear flow guide and double ball screw clean to ensure the stability and precision of transmission.

● Gap elimination: Regularly check and adjust the gap between the sliding of the grinding head holder to ensure the accuracy of repetitive positioning.

7. Preparation before processing

● Read the instruction manual: Before operating the newly purchased edge grinder, you should read the instruction manual in detail to understand the transmission principle and operation method of the machine.

● Master the maintenance knowledge: the operator needs to master the maintenance knowledge of the machine, in order to get ready for the operation of the machine.

8.Troubleshooting

● Stop the machine for inspection: Once the abnormality is found, the processing should be stopped immediately and the machine can be restarted only after troubleshooting.

● Professional maintenance: For complex faults that cannot be solved by yourself, you should contact professional maintenance personnel or manufacturer's service in time.

In addition, after understanding the above, the following points should be noted during operation:

● Avoid direct manual contact with dangerous parts such as the grinding head during machine operation.

● Keep the work area well ventilated to prevent coolant mist from affecting the operator's health.

● Take fire precautions, as the high temperatures generated by the grinding process can cause fires.

● Observe local safety regulations and environmental protection legislation, and dispose of waste materials generated during the grinding process in a reasonable manner.

Overall, maintenance and troubleshooting of glass bilateral edge grinding machines are key to ensuring production quality and efficiency. The performance and stability of the equipment can be significantly improved through routine maintenance, proper operation and timely troubleshooting. Operators should familiarise themselves with the equipment manual and master the relevant maintenance and handling techniques, while paying attention to safe production to protect the operator's health and production safety. If complicated problems are encountered, contact professionals for repair in time to ensure that the equipment serves the glass deep-processing industry in a long-term and stable manner.