INDUSTRY NEWS

How does a glass bilateral machine work?

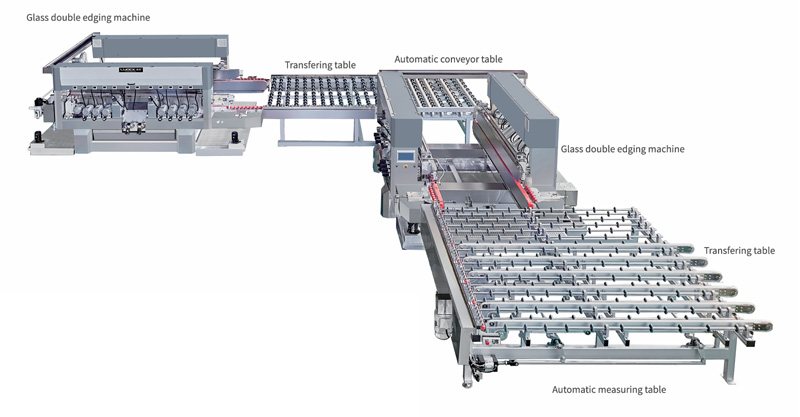

Glass Double Edge Machine is mainly used to grind and polish both sides of glass by grinding head motor and grinding wheel to achieve fine processing of glass.

In today's glass deep processing field, glass double edged machine plays an indispensable role. This type of machinery not only greatly improves the efficiency and quality of glass processing, but also provides the possibility of producing more complex and beautiful glass products. The following is an in-depth discussion of the working principle and operation of the glass bi-lateral machine, so as to have a comprehensive and in-depth understanding of this important equipment:

1.Working Principle

● Matching of grinding head motor and grinding wheels: The core technology of the glass bilateral machine lies in the use of the power of the grinding head motor to drive the grinding wheels of various sizes and materials to grind and polish the glass. In this process, the rotational speed of the grinding head motor and the material and grain size of the grinding wheel have a direct impact on the effect of glass processing. According to different processing requirements, the operator can choose the appropriate grinding wheel, so as to realise the rough grinding, fine grinding, polishing and other processes in one go. This not only improves the working efficiency, but also ensures the quality of glass processing.

● One-time processing and shaping: One of the design advantages of the glass double-edged machine is the ability to grind and polish both edges of the glass at the same time, i.e. double-edged processing. This design makes glass processing more efficient and also reduces processing errors caused by turning the glass several times. Driven by the grinding head motor, the double edged glass machine is able to precisely control the depth and width of grinding, ensuring that each piece of glass meets the predefined processing standards.

2.Operation Steps

● Preparation: Before operating the glass double edger, the operator needs to make sufficient preparation. This includes wearing the necessary labour protection equipment, such as gloves and protective glasses, to ensure safety during the process. Subsequently, parameters such as the amount of roughing and finishing wheel grinding, thickness and width on the machine are adjusted according to the size of the glass to be processed and the processing requirements. These preparations may seem simple, but they are vital to ensuring processing quality and operational safety.

● Processing procedure: Switch on the power supply, start the water pump and grinding head motor, and make sure that all the equipment operates normally. Then, the glass to be processed will be placed on the feeding frame and enter the upper and lower clamping section through the synchronised conveyor. At this stage, the glass will go through a series of processing procedures such as rough grinding, fine grinding and polishing, and finally the processed glass will be taken down from the discharging rack. The whole process is smooth and continuous, which greatly improves the production efficiency.

3.Precautions

● Operation specification: In order to ensure safe production and improve the processing quality, the operation of the glass double edging machine must follow strict operating procedures. This includes wearing correct labour protection equipment, adjusting machine parameters according to the operating instructions, and regularly checking and maintaining the equipment. Especially during the operation of the machine, it is important to avoid direct hand contact with grinding wheels and other dangerous parts to prevent workplace accidents.

● Maintenance: As a precision processing equipment, the maintenance of glass bilateral machine is equally important. Regular inspection and replacement of key components of the machine, and timely cleaning of accumulated dust and debris can effectively extend the service life of the machine and ensure the stability of the processing results. Therefore, formulating and executing a maintenance plan is essential to ensure the long-term stable operation of the equipment.

In addition to this, it is also beneficial to know some additional information brought by the glass bilateral machine. For example, knowing how to select different types and sizes of grinding wheels can further enhance processing efficiency and product quality. Meanwhile, understanding the features and performance of glass bilateral machines produced by different manufacturers in the market can help companies make a more reasonable choice according to their needs. When operating the glass bilateral machine, the following points should also be noted:

● Ensure that the power supply is stable, to avoid the normal operation of the machine being affected by voltage fluctuations.

● Use professional tools to adjust the parameters of the machine, to avoid improper adjustment leading to a decrease in processing accuracy or damage to the equipment.

● In the process of processing, you should always pay attention to the glass feeding situation and processing status, once found abnormalities should immediately stop the machine for inspection.

In general, the glass bilateral machine has occupied an important position in the glass deep-processing industry with its unique working principle and efficient processing capability. By mastering its operating steps, precautions and maintenance knowledge, not only can give full play to the performance of the glass bilateral machine, but also ensure the safety and efficiency of the processing process. In the future development, with the progress and innovation of technology, the application of glass double edged machine will be more extensive, providing strong support for the production of more high-quality and diversified glass products.