INDUSTRY NEWS

What is the difference between a glass single edge machine and a double edge machine?

In the field of glass processing, single-sided and double-sided machines have their own characteristics, and there are significant differences between them in terms of productivity, precision, and applicable environments. Specifically analysed as follows:

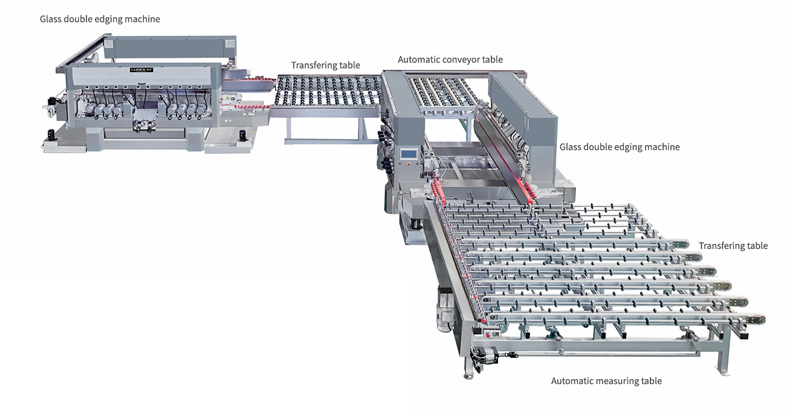

1. Processing efficiency single-sided machine: single-sided machine can only grind one edge of the glass per operation. For example, for a piece of glass with four edges, at least four operations are required to complete the grinding of all edges. Double-sided machine: double-sided machine can grind two opposite sides of the glass at the same time, so for the same piece of glass, double-sided machine only needs two operations to complete the grinding work, greatly improving the production efficiency, this kind of machine is especially suitable for those enterprises that need to deal with a large number of orders quickly, because it can almost cut the production time in half.

2. Accuracy Single Edge Machine: The accuracy of single edge machine may be affected by multiple clamping and grinding, because after each grinding of one edge, the glass needs to be repositioned for the next edge grinding. Double-sided machine: Double-sided machine can better maintain the parallelism and dimensional accuracy of the glass due to the simultaneous grinding of two opposite edges, especially when dealing with high-volume glass grinding production, its accuracy advantage is more obvious, which is especially important for architectural or automotive glass requiring high precision.

3. Applicable Scenarios Single Side Machine: Single side machine is suitable for small batch production or scenarios with special requirements on the number of grinding times. Bilateral machine: Bilateral machine is more suitable for mass production, especially in the standardised and scaled production line, which can significantly improve the production efficiency and processing quality.

4. Operation Complexity Single Side Machine: The operator needs to set the grinding settings for each side separately, the operation is more complicated and requires higher skills for the operator. Double-sided machine: double-sided machine due to the reduction of operating steps, the operation is more simple, the operator's skills requirements are relatively low, easy to quickly get started.

5. Cost investment single-side machine: single-side machine initial investment is lower, but more manual operation, may increase labour costs in the long term. Double-sided machine: the initial investment of double-sided machine is relatively high, but due to its high efficiency and low operating difficulty, it can achieve return on investment in a relatively short period of time.

In response to the above analysis, the following points of advice are provided:

● When selecting an edgebanding machine, factors such as actual production requirements, budget constraints, and operator skill level should be considered.

● Single edge machines have a lower initial investment, but more manual operations, which may increase labour costs in the long run. This is a viable option for companies with limited capital but sufficient labour.

● Double-sided machines have a relatively high initial investment, but due to their high efficiency and low operating difficulties, a return on investment can be realised in a relatively short period of time. This is a worthwhile investment for companies seeking long-term benefits.

In response to the above analysis, the following suggestions are provided: when choosing an edgebander, factors such as actual production needs, budget constraints, and operator skill level should be considered. For small glass processing enterprises that have just started their business or have a small production volume, they can consider introducing a single edge machine first. If it is a large-scale production or a large enterprise pursuing high efficiency and precision, it should consider purchasing a bilateral machine. Overall, double-sided machines perform better in terms of processing efficiency, precision, ease of operation and suitability for mass production, while single-sided machines still have a place because of their relatively low cost and suitability for special processing needs. Users should decide which machine is better for them based on their production scale, processing needs and budget. Understanding these differences will help you make sound investment decisions and pave the way for improved productivity and product quality.