INDUSTRY NEWS

What are the specific classifications of glass edging machines?

As an important equipment in the glass deep processing industry, glass grinding machine, its technical performance and scope of application directly affect the efficiency and quality of glass processing. According to different processing needs and glass types, glass grinding machine can be divided into a variety of types, various types of grinding machine has its own characteristics and scope of application. The following is a specific introduction:

1. Single-arm profiled edge grinding machine

Wide range of applications: the most important feature of this type of machine is its wide range of applications, which can grind straight edges, round edges, duckbill edges and bevelled edges, and can deal with round, oval and shaped workpieces.

Low price: due to the simple structure, the manufacturing cost is relatively low, which makes the single-arm profiled edge grinder cheaper in price, generally about 20,000 yuan for domestic models can be bought.

Irregular workpiece processing capacity: equipped with independent suction cups and die backing, the single-arm profiled edge grinder can process some irregularly shaped workpieces.

2.Glass straight edge machine

Single-purpose: Straight line edge grinding machine is mainly used for grinding all kinds of straight edges, which is more single-purpose compared with the profile machine.

High efficiency: Due to the continuous grinding, the productivity of straight line edge grinding machine is high, which is suitable for mass production.

Large-size glass grinding capacity: linear edge grinding machine can grind large-size flat glass, suitable for large glass processing.

Diversified classification: according to the different straight edges that can be ground, linear edge grinding machine can be further divided into different types of subcategories, such as linear edge grinding machine, linear bevelling machine and linear round edge machine.

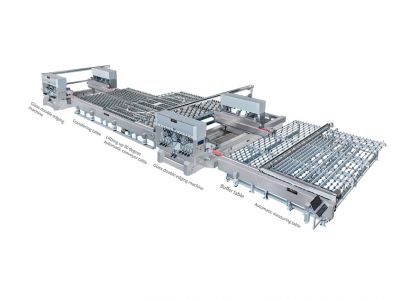

3. Glass Bilateral Machine

Classification according to width: Bilateral grinding machine can be divided into small and medium-sized and large-sized according to the different width of the grinding glass. The grinding width of less than two metres is called medium and small bilateral grinding machine, while two metres and more than two metres is called large bilateral grinding machine.

Grinding head configuration: small and medium-sized bilateral mill is usually configured with four, six, eight, twelve grinding heads, etc., while the large bilateral mill has sixteen, twenty, twenty-two grinding heads, etc., in order to adapt to the different widths of the glass grinding needs.

4.Edge grinding machine by mould

Ability to handle complex shapes: the die grinder is able to grind glass with the help of a template, which makes it suitable for processing complex shapes of glass edges.

Customised production: these machines are suitable for the production of glass products with special shape requirements, which facilitates personalised further processing of glass.

In addition, when choosing a glass edge grinding machine, the following factors should also be considered to ensure that the equipment purchased can meet the production requirements:

1. Define the processing needs, including the type of glass, size, shape of the ground edge, etc..

2. Consider production efficiency. Continuous or high-efficiency equipment may be more suitable for mass production.

3. Consider the reliability and durability of the equipment and select a reputable manufacturer.

4. Budget is a key factor in decision-making, and a cost-effective edgebander should be selected.

5. Considering the possibility of future production expansion, choosing upgradable or multi-functional equipment may be more long-term vision.

In summary, there are several classifications of glass edging machines, including single-arm profile grinders, linear grinders, double-edge grinders, and die leaning grinders. Each type of grinder has its own unique characteristics and scope of application, and choosing the right glass grinder requires full consideration of processing needs, productivity, equipment reliability, budget and future expansion and other factors. The right choice will not only ensure normal production, but also play a role in extending the life of the machine, thus promoting the maximisation of business benefits.