COMPANY NEWS

Unveiling the Mysteries of Double Edging: Solutions Offered by Luockbas

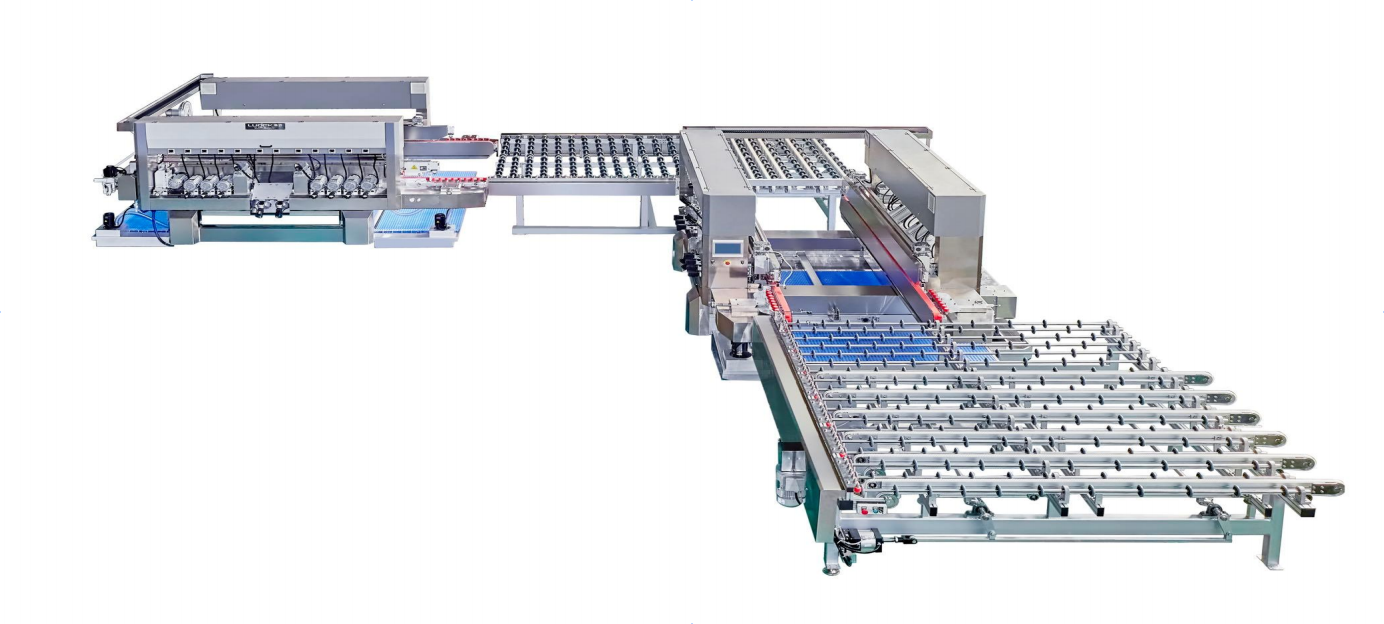

In the modern glass processing industry, edging machines play an indispensable role as one of the key pieces of equipment. Particularly, double edging machines have become the ideal choice for architectural, industrial, and photovoltaic glass processing due to their high efficiency and precision. This article will delve into the working principles, applications, and impacts of double edging machines on industry development, helping you gain a better understanding of this important equipment.

What is a Double Edging Machine?

A double edging machine is specifically designed for the precise processing of glass edges, capable of grinding both edges of the glass simultaneously. Compared to traditional single edging machines, double edging machines offer significant advantages in processing efficiency and product quality. According to Statista, the global glass edging machine market is projected to reach $800 million by 2026, with an annual growth rate of approximately 10%. This underscores the importance and potential of double edging machines in the market.

Working Principle of Double Edging Machines

Double edging machines typically utilize automated control systems in conjunction with high-precision grinding heads to achieve rapid edge processing of glass. The working principle mainly involves the following steps:

- Glass Fixation: The glass is secured in a specific position within the edging machine to ensure it remains stationary during the grinding process.

- Conveyor Movement: The fixed glass moves through a conveyor belt to the grinding area, ensuring each piece of glass is processed accurately.

- Grinding Process: Grinding heads operate simultaneously on both sides, often equipped with multiple grinding heads to perform fine processing at different angles. The rotation speed and pressure of the grinding heads can be adjusted based on the type of glass and processing requirements.

- Automatic Monitoring: Many modern double edging machines feature intelligent control systems that monitor the grinding process in real-time and automatically adjust grinding parameters based on data feedback to ensure optimal results.

Advantages of Double Edging Machines

- High Efficiency: Double edging machines can grind two edges simultaneously, significantly enhancing production efficiency. Data shows that factories using double edging machines can shorten production cycles by over 30%. For example, a construction glass processing company successfully increased its daily output from 2,000 square meters to 2,600 square meters by introducing double edging machines. Recently, LUOCK implemented a double edging line solution for a client in Spain, which is expected to yield substantial improvements in production efficiency in the near future.

- High Precision: Advances in technology have enabled modern double edging machines to achieve high-precision grinding, ensuring that every piece of glass meets consistent quality standards. Many customers have reported a 15% increase in product qualification rates after using double edging machines. This improvement not only reduces scrap rates but also lowers production costs, enhancing overall corporate efficiency.

- Strong Adaptability: Double edging machines are suitable for various glass processing needs, including architectural glass, automotive glass, and photovoltaic glass. For instance, in photovoltaic glass production, double edging machines efficiently process lead edges, meeting the industry's demands for high quality and efficiency.

- Energy Efficiency and Environmental Friendliness: Many new double edging machines are designed with energy efficiency in mind, utilizing energy-saving motors and high-efficiency grinding systems to reduce energy consumption. One edging machine manufacturer reported a 20% reduction in energy consumption for its latest model, which complies with international environmental standards. This initiative aligns with global environmental trends and helps customers save on production costs.

Foshan Luockbas Solutions

As a leading manufacturer of edging machines, Foshan Luockbas Glass Precision Machinery Co., Ltd. offers a range of specialized edging solutions designed to meet diverse customer needs:

- Architectural & Industrial Glass Double Edging Production Line Solutions: We provide efficient double edging equipment tailored for the construction industry, enhancing production efficiency and product quality. Our equipment undergoes rigorous testing to ensure stable operation under various conditions, helping customers reduce costs. For instance, the glass processing efficiency of a large construction project improved by 40% after implementing our solutions.

- Photovoltaic Glass Pencil Edging Production Line Solutions: The photovoltaic industry has specific glass processing requirements. We offer specially designed pencil edging machines that ensure compliance with industry standards during production while enhancing the overall performance of photovoltaic modules. Recently, we provided a complete production line for a well-known photovoltaic company, significantly boosting its market competitiveness.

- Jumbo Size Glass Edging Production Line Solutions (Up to 20,000mm): As market demand for oversized glass increases, our equipment meets customer needs for processing glass up to 20,000mm in length, ensuring a combination of high efficiency and precision. We have previously provided such solutions for a large commercial building, ensuring both the aesthetic appeal and safety of the building's exterior.

- Irregular Shape Glass Edging Machine Solutions (Horizontal Processing): To cater to the processing demands of uniquely shaped glass, we offer flexible edging solutions capable of handling various complex shapes, enhancing production flexibility. By using our irregular shape edging machines, one client successfully processed multiple non-standard glass shapes, expanding its product line to meet market diversity.

- Cutting-Edging-Washing Automatic Production Line Solutions: Our integrated production line design improves efficiency and reduces labor costs, providing a more comprehensive service for customers. For example, a client experienced a 40% increase in production efficiency after adopting our integrated production line, while also reducing worker workload and enhancing the overall working environment.

- Turnkey Project Layout Design & Solutions: We provide comprehensive services from equipment selection to production line layout, ensuring smooth project implementation and achievement of expected goals. In multiple projects, our turnkey services have helped clients save valuable time and resources, allowing them to focus more on their core business.

Industry Trends and Market Outlook

With the continuous development of the global construction industry and increasing environmental awareness, market opportunities for edging machines will continue to expand. As a crucial piece of equipment in the glass processing industry, the demand for double edging machines is expected to maintain steady growth. Market research indicates that by 2026, the global glass edging machine market will reach $800 million, with an annual growth rate of approximately 10%. This trend presents unprecedented market opportunities for industry leaders like Foshan Luockbas.

Conclusion

In conclusion, double edging machines are an essential component of the modern glass processing industry, driving continuous development through their high efficiency and precision advantages. Foshan Luockbas will remain committed to technological innovation, providing high-quality edging solutions to help clients maintain a competitive edge in a challenging market. We firmly believe that through ongoing technological advancements and service optimizations, we can deliver greater value to our customers. For more information about our products, please feel free to contact us. We look forward to working together to create a brighter future!